What is invariant analysis technology?

Invariant analysis technology, one of NEC's cutting-edge AI technology suite (NEC the WISE), has been added to Advanet's lineup of edge computing products.

Automatically extracts invariants (invariant relationships) that exist between sensors and creates a monitoring model, enabling early detection of abnormalities

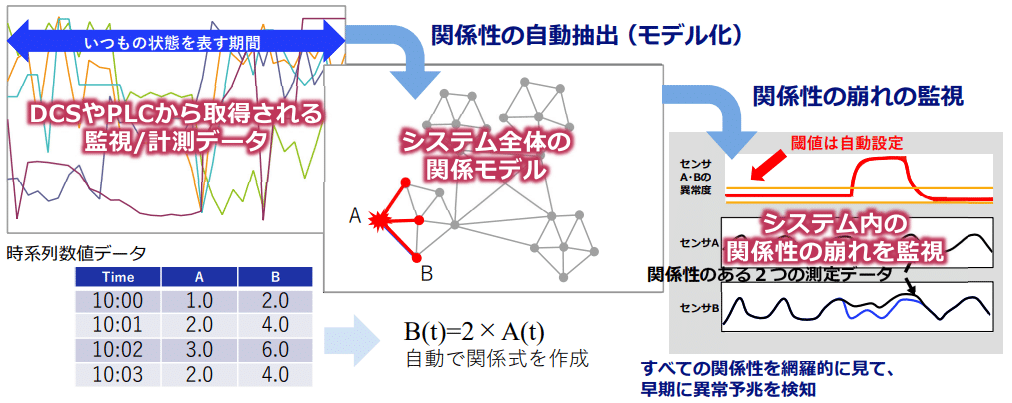

Automatically extracts and visualizes invariants that exist between measurement items (sensors) from control and operational data acquired from plants and equipment. This makes it possible to extract equipment movements that even skilled engineers could not grasp. In addition, since the relationship between sensors can be comprehensively visualized, the characteristics of equipment operation can be extracted without overlooking them.

ABOUT NEC'S INVARIANT ANALYSIS TECHNOLOGY

We look forward to hearing from you!

structure

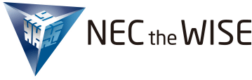

We will introduce the mechanism of industrial process enhancement through invariant analysis technology.

- Data collection: Collects production/process data from a large number of sensors installed throughout the manufacturing site in conjunction with the DCS and PLCs that monitor/control the plant.

- Model Creation: Create an invariant model that represents the "usual state" of the system using the collected data.

- Real-time analysis - monitoring: Using modeled "usual conditions," current sensor data is compared in real time to detect any "out of the ordinary" conditions.

- Anomaly detection: If the system identifies an "unusual" condition, it alerts the operator.

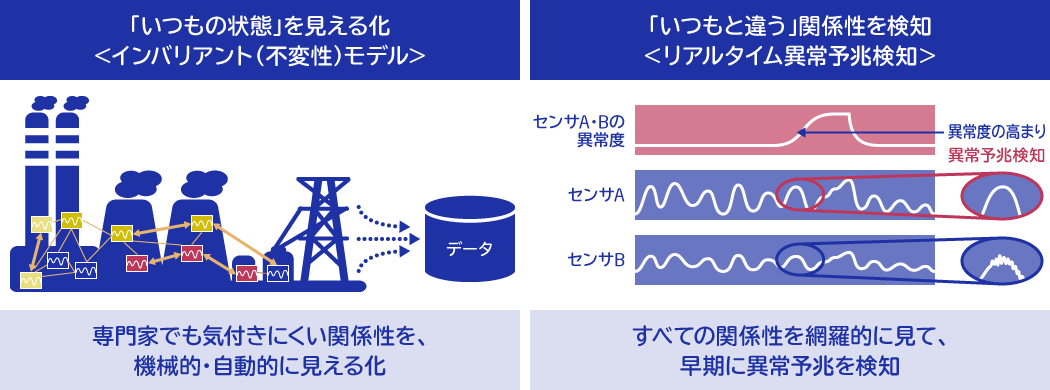

Early detection of small movements of equipment that lead to failures enables predictive maintenance and reduces the occurrence of unexpected failures. This will enable a shift from the current post- and preventive maintenance to predictive maintenance. This will also reduce maintenance costs and realize further improvements in efficiency and safety.

Advantages of Introducing Invariant Analysis Technology

- Increased uptime: AI-powered monitoring identifies problems before they escalate, significantly increasing machine availability and reducing downtime.

- Reduced maintenance costs: Early detection of potential problems allows timely maintenance, reducing the need for emergency repairs and associated costs.

- Quality Monitoring: Continuous monitoring of equipment conditions ensures high product quality and minimizes the possibility of defective products.

- Labor Efficiency: Automating the monitoring process frees up valuable human resources, allowing staff to focus on more important tasks.

- Scalability and integration: Invariant analytics technology is designed to integrate with existing infrastructure, allowing for scalable solutions that grow with business needs.

- Safety and reliability: Detect problems before they occur for a safer work environment and more reliable operation.

- Knowledge transfer: By capturing and storing the detailed expertise of skilled operators, know-how can be passed on more smoothly to newcomers.

ABOUT NEC'S INVARIANT ANALYSIS TECHNOLOGY

We look forward to hearing from you!

Features / Features Features Synergy

Invariant analysis technology enables safe and efficient system operation by automatically learning and monitoring system behavior and detecting signs of abnormalities. NEC Advanced Analytics - Invariant Analysis" is a software product that packages this invariant analysis technology for easy implementation.

Visualization of system monitoring status and AI Engine Package

Web UI for displaying the system monitoring status and analysis results (abnormality prediction and influence range) is packaged as software. This allows users to perform standard analysis and operation evaluation using past data (e.g., CSV files of time-series values) by themselves. Advanet can provide the AI engine together with hardware with a small footprint, making it easy to add the AI engine to an existing monitoring and control system.

Fanless Box PCs for Various Environments

Do you ever struggle to install a server to collect data obtained from sensor modules? In some cases, due to various restrictions, the server must be installed close to the site, requiring a PC that is more environmentally tolerant. Advanet's fanless Box PCs have a structure that can withstand a wider range of operating temperatures and dusty environments, making them ideal for use as edge servers.

case study

Case 1: Large-scale plant - Increased availability

Large-scale plants require extensive and extensive equipment and have traditionally relied on manual inspections and centralized monitoring. However, manual inspections can miss minute changes, and centralized monitoring alone makes it difficult to quickly detect abnormalities from large amounts of data. Invariant analysis technology can capture such minute changes in real time, enabling proactive response before serious problems occur and improving uptime.

Case 2: Production Line - Quality Improvement

In production lines for mass production, various sensor data such as temperature, pressure, and processing time are monitored to maintain quality. Conventional methods require specialized knowledge and time-consuming labor. Invariant analysis technology detects even the slightest changes that affect quality in real time, preventing events that would otherwise result in the mass production of defective products.

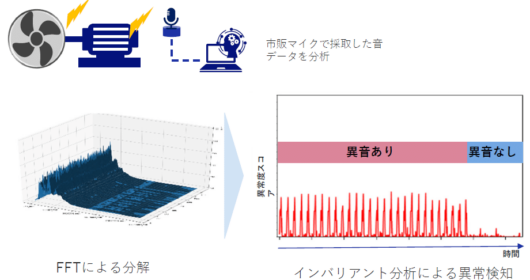

Case 3: Abnormality detection by sound

One of the data that invariant analysis technology excels at is sound. Sound is very effective in detecting abnormalities in exhaust fans, motors, turbines, and other equipment. Invaliant models are created from the sound of equipment in operation, enabling predictive maintenance through the detection of abnormal noises. Since the analysis is tailored to the operating conditions, abnormalities can be detected even in the presence of ambient noise.

Case 4: Lockheed Martin Corporation (video)

Lockheed Martin has utilized invariant analysis technology in the testing of its newly developed manned spacecraft, Orion, to shorten development time and make more efficient use of its workforce. Invariant analysis technology is also effective in the development and improvement of new products.

Products verified to work with invariant analysis technology

Advanet offers software and hardware in one package to enable a smoother implementation of invariant analysis.